Sapphire Systems has developed

technology to grow some of the

largest sapphire plates in the world.

Soon we will be delivering high-performance windows to both commercial and military customers.

- High strength

- Excellent transparency

- Superb high-temperature performance

- Exceptional abrasion and corrosion resistance

Military

Applications

Sapphire’s exceptional hardness and strength make it ideal for challenging military environments.

Sapphire windows are used to protect range finders, infrared cameras, and other optical systems - as well as personnel. Sapphire is the material of choice for bullet-proof windows.

Semiconductor

Applications

Sapphire’s extreme resistance to corrosion makes it ideal for use in the corrosive environments of computer‑chip manufacturing.

Sapphire is used for windows, wafer carriers and other hardware.

Capabilities

Sapphire Systems is growing optical-quality sapphire plates 15-5/8 inches wide.

We will soon offer as standard production plates 30 inches by 15-5/8 inches (by 3/8 inches thick). Larger plates will be available on request.

Growth Method

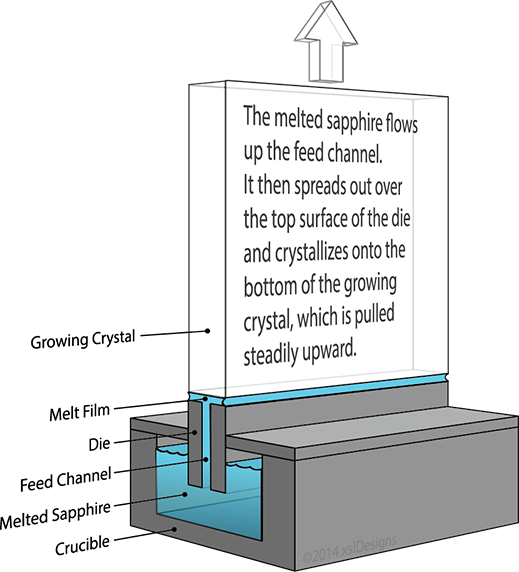

Edge-defined, Film-fed Growth (EFG) is considered the ideal method for growing large-area plates.

The essence of EFG is that the crystal is grown from the film of melted sapphire on top of the die.

History

Sapphire Systems was incorporated in 2007 by Charles Allmon and John Outwater to commercialize crystal-growth innovations developed in a garage laboratory. Shortly after, Sapphire Systems moved to a larger facility in Bedford, MA to allow development of larger systems and to start commercial production.

Sapphire Systems has produced and sold optical sapphire fiber, and sapphire ribbon for superconductor substrates.

After years of development, it will soon start pilot production of some of the largest commercially-available sapphire plates in the world.

Sapphire Systems has been awarded three US patents, an R&D 100 Award, and an SBIR Award.

Awards

– Apparatus and Methods of Growing Void-Free Crystalline Ceramic Products

- Targeted Heat Control System and Method for Integrated Crucible and Die System for Sapphire Sheet Growing

- Integrated Crucible and Die System for Sapphire Sheet Growing

- Window Holder (pending)

- Thermal Chimney (pending)

- Feed System (pending)

Optical Grade Sapphire Manufacturing Growth Process for IR Window Applications

R&D 100 AwardSuperconducting Wires by Epitaxial Growth on SSIFFS

Properties

of Sapphire

General

Chemical Formula: Al2O3 (aluminum oxide)

Names: corundum, sapphire, alpha alumina

Crystal System: trigonal

Class: hexagonal-scalenohedral

Thermal

Melting Point: 2053°C (3727°F)

Maximum-Use Temperature: 2000°C

Specific Heat: 0.18 cal/g-K (25°C), 0.3 cal/g-K (1000°C)

Thermal Conductivity: 40 watts/m-K (25°C), 10 watts/m-K (1000°C)

Thermal Expansion Coefficient (25 - 1000°C): 8.8 x 10-6 K-1 parallel to C-axis, 7.9 x 10-6 K-1 normal to C-axis

Physical/Mechanical

Density: 3.97 g/cm3 (25°C)

Young's Modulus (parallel to C axis): 435 GPa (63 x 106 psi) at 25°C, 386 GPa (56 x 106 psi) at 1000°C

Shear Modulus: 175 GPa (26 x 106 psi)

Poisson's Ratio: 0.27 - 0.30

Flexural Strength: 1035 MPa (150 ksi) parallel to C axis (25°C), 760 MPa (110 ksi) normal to C axis (25°C)

Compressive Strength: 2 GPa (300 ksi) 25°C

Hardness: 9 Moh's scale. 1900 Knoop (parallel to C axis), 2200 Knoop (normal to C axis)

Optical

Uniaxial Negative Refractive Index (parallel to C axis): Ordinary ray No = 1.768, Extraordinary ray Ne = 1.760,

Birefringence = 0.0087

Temperature Coefficient of Refractive Index: 13 x 10-6 K-1 (visible range)

Spectral Emittance: 0.1 (1600°C)

Spectral Absorption Coefficient: 0.1 - 0.2 cm-1 (25 - 1600°C)

Electrical

Volume Resistivity (ohm-m): 1016 at 25°C, 1010 at 500°C, 107 at 1000°C

Dielectric Strength: 480,000 volts/cm (1,200 volts/mil)

Dielectric Constant (25°C, 103 - 109 Hz): 11.5 parallel to C axis; 9.3 normal to C axis

Loss Tangent (< 1010Hz, 25°C): 8.6 x 10-5 parallel to C axis, 3.0 x 10-5 normal to C axis

Magnetic Susceptibility: 0.21 x 10-6 parallel to C axis; 0.25 x 10-6 normal to C axis

Chemical

Weathering Resistance: Unaffected by atmospheric exposure

Sea Water Resistance: Unaffected by marine exposure

Biological Resistance: Unaffected by in-vivo exposure; non-thrombogenic; non-reactive with body fluids

Sapphire Systems is located

along the 128 loop, northwest of Boston, MA

Sapphire Systems, Inc.

19A Crosby Drive #10

Bedford, MA 01730

joutwater@SapphSys.com